History of Ingersoll Tillage -there was a time when farming was done at a slower pace. It was a time when horses and oxen provided the pulling power and farmers walked the field behind them. Fields were tilled with a single coulter blade fastened in front of a plow that would cut through crop residue and break up clumps of sod prior to turning the soil. And we were there.

In 1884, Steven Ingersoll took over a small coulter disc manufacturing company in Sandoval, Illinois. The discs produced there were the state of the art, back then, but everything was about to change.

In 1905, the company moved to Galesburg, Illinois, was renamed the Galesburg Coulter-Disc Company, and grew very rapidly as farming was changing dramatically.

By 1920, tractors were now pulling coulters through the soil faster and faster, slicing through fields and slamming into rocks at a pace nobody could have imagined just a few years earlier. The old discs, with their old steel were wearing out too fast and breaking too often.

Roy Ingersoll, Steven's son, began experimenting with new heat treating processes and improved manufacturing techniques. These resulted in discs that could hold their shape and sharpness under the most demanding conditions. This new technology, made it possible to create blades that were slightly cup shaped (concave) to more aggressively manipulate the soil.

Since then, farms have continued to increase in size, tractors have continued to increase in power and Ingersoll has continued to improve our blades to meet each of these new challenges. Today, the Ingersoll Tillage Group is built upon the legacy of Steven and Roy Ingersoll.

Our North American manufacturing center is the most modern in the industry, on a site that has been producing tillage and planting equipment and components for over 100 years. Proud of our heritage, we are dedicated to serving the farmer through innovation in new products and support.

At Ingersoll, we use an advanced proprietary boron steel alloy that's the best in the industry. This very special steel alloy means that our blades are among the hardest you can buy.

Hard steel is a good thing. But a disc also has to be flexible to resist chipping in rocky soil. Disc metal has to possess a quality that material scientists refer to as "fracture toughness" - the ability to resist fractures.

No farmer wants to pick up broken disc shrapnel with a harvester at the end of the season.

Hardness. Flexibility. Sharpness. Ductility. Fracture toughness. We know of no other disc you can buy that matches us in all of these critical properties.

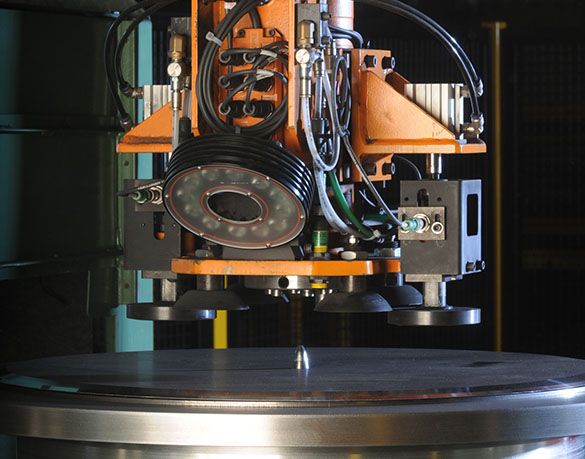

For the very best coulters and discs, advances in material science have to be matched with advances in material handling and manufacturing processes. This is where we excel. Our metal forming and heat treating operations as well as robotic cutting and grinding machines produce strict dimensional control, edge sharpness and wobble tolerances that exceed every OEM specifications on the planet.